Key Challenges in Test Bench Development

- Navigating Compliance and Safety Standards

Test benches in regulated industries must adhere to rigorous standards such as CE marking and EU conformity directives. Achieving compliance requires meticulous attention to detail and can become a complex, time-consuming task without the right tools to manage and document regulatory requirements throughout the development process. - Managing System Complexity and Risk

Test benches often involve monitoring industrial devices or simulating critical operations, introducing significant operational risks. Inadequate risk management can lead to equipment failure, safety hazards, and inaccurate test results. Integrating robust risk management strategies from the outset is crucial to ensure system reliability and operator safety. - Ensuring Seamless System Integration

Integrating various hardware and software components can present many challenges, especially when multiple devices need to operate synchronously. Effective system integration simplifies maintenance, ensures accurate data acquisition, and facilitates rapid troubleshooting. Without seamless integration, system performance can suffer, and diagnosing issues becomes more difficult. - Documentation and Traceability

Proper documentation is not only required for compliance with regulatory standards, but ensures transparency and aids in future maintenance. However, tracking every component and process can be overwhelming without efficient tools to support documentation and traceability.

How test.con Addresses These Challenges

Streamlined Graphical Programming for Real-Time Applications

test.con offers intuitive, drag-and-drop graphical programming for Gantner’s Q.series X controllers, eliminating the need for traditional coding. Users can efficiently design custom logic, data processing algorithms, and visualization functions. This approach accelerates development and makes programming accessible to engineers who may not have extensive software development experience.

Powerful Risk and Compliance Management

With its model-based development approach, test.con allows for the integration of complex control logic and safety functions at every stage. Regulatory requirements can be managed within the software, enabling the incorporation of industry standards and the documentation necessary for CE certification. test.con also supports programmable automation controller (PAC) functionality, providing the flexibility to meet specific safety and regulatory demands across different industries.

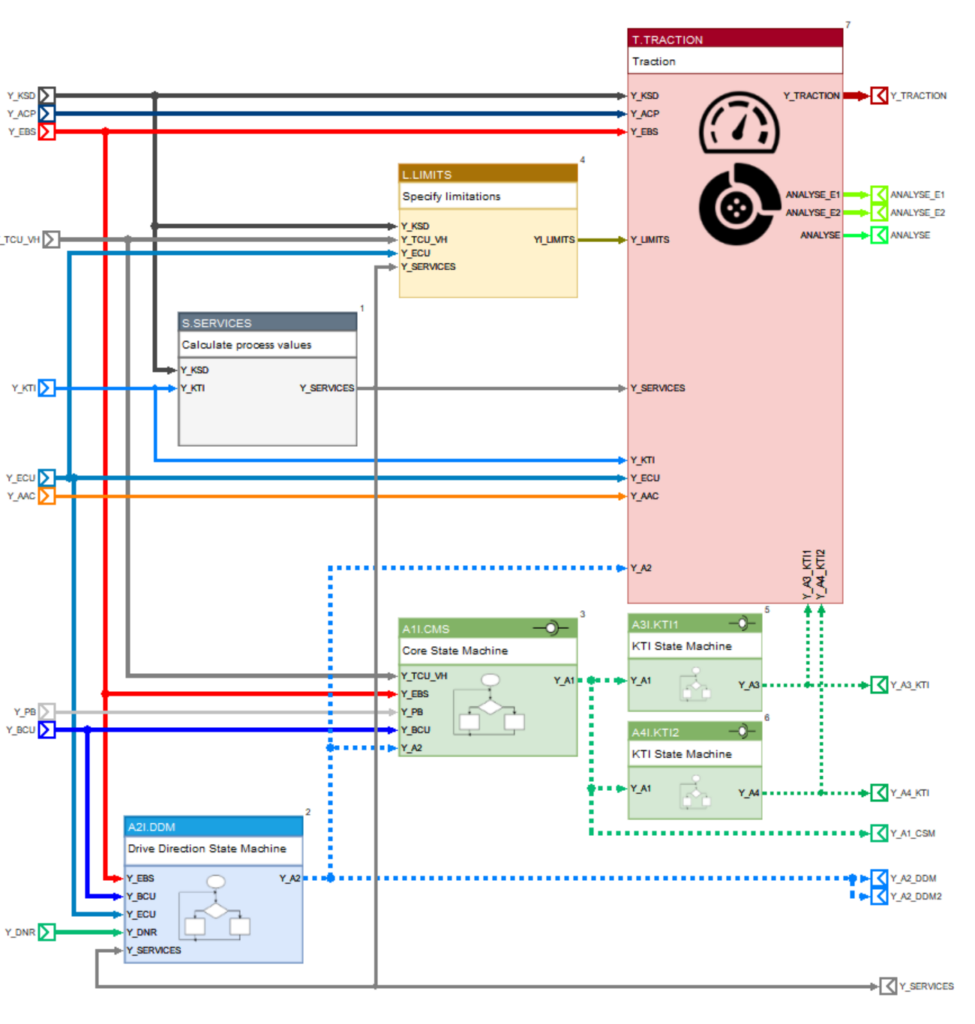

Integrated System Architecture and HMI Design

test.con has the ability to design human-machine interfaces (HMIs) directly within the platform. This capability enables operators to visualize and control the entire system in real-time, adding critical layers of monitoring and control for risk mitigation and seamless system integration. By unifying system architecture and HMI development, test.con enhances operational efficiency and reduces complexity.

Built-In Documentation and Traceability

test.con integrates documentation and traceability into the development process. From initial requirements analysis to final testing, the software supports comprehensive tracking of every element within the project, from individual components to complete system architectures. This integrated documentation facilitates CE compliance and provides a complete system record for future maintenance and audits.

Partner with Gantner Instruments for Effective Test Bench Solutions

Whether you’re developing a complex test bench or seeking support for regulatory compliance and risk management, Gantner Instruments, in partnership with ProSign, offers the expertise and technology to assist you. test.con provides a comprehensive solution for building reliable, compliant, and efficient test benches tailored to your specific project needs.

Get Started with test.con

Ready to overcome the challenges of test bench development? Contact our team for a consultation, and we’ll guide you in implementing a solution that meets the highest industry standards.

Learn more about test.con and enhance your test bench development today.

Want to see a hands-on example?

This video guides you through all the required steps, including system design, modeling, and creating a curve generator.

More articles

Precision Quiescent-Current Measurement with Q.series XL Slimline A108 2SC

Quiescent current measurement is essential across various industries, notably in the development of battery-powered devices, automotive electronics, and energy-efficient technologies. Also known as standby current, this crucial parameter measures the current in electronic systems during idle states, significantly impacting power consumption, battery longevity, and overall efficiency. Minor inaccuracies in its measurement can lead to considerable consequences.

Read more...Testing of Dynamic and Strength

During operation of wind turbines high dynamic loads are considered. Therefore, static and dynamic strength and fatigue analysis are absolutely necessary on rotor blades of wind turbines.

Read more...The Story Behind GI.blop: A home-brewed NEIPA Christmas treat from Austria

Christmas is approaching, and with it comes the festive season of sharing and special gestures. This year, we at Gantner Instruments wanted to give our customers and partners something unique for the holidays. So we created a special handcrafted beer we call GI.blop that is not only a great gift but also tells a story.

Read more...Precise Temperature Measurement with Pt100

Temperature measurement is one of our key competence areas. Here we maintain a position of global leadership. Our advanced 4-channel Q.bloxx A105 measurement module sets new standards in terms of stability and precision. For many different applications, the extremely precise and stable measurement of temperatures is an absolute prerequisite for the control of processes or the success of product innovations. In addition to the essential precision, particularly important aspects of this are the maintenance of stability when changes occur in the ambient temperature and ensuring long-term stability.

Read more...