In the following examples of applications, our products are being used with great success:

MAHLE Behr

Development and testing of air conditioning components for the automobile industry. The extremely high demands for efficiency make it necessary when measuring heat levels to ensure a very precise recording of temperatures. For this reason, our modules have been employed in this area for several years.

German Weather Service (DWD)

The weather stations installed throughout the country have to deliver reliable measurement values at all extremes of external temperature. Whether in the winter in the Alps or in the summer at the seaside, Gantner modules are used by the DWD to produce accurate measurements, whatever the ambient temperature.

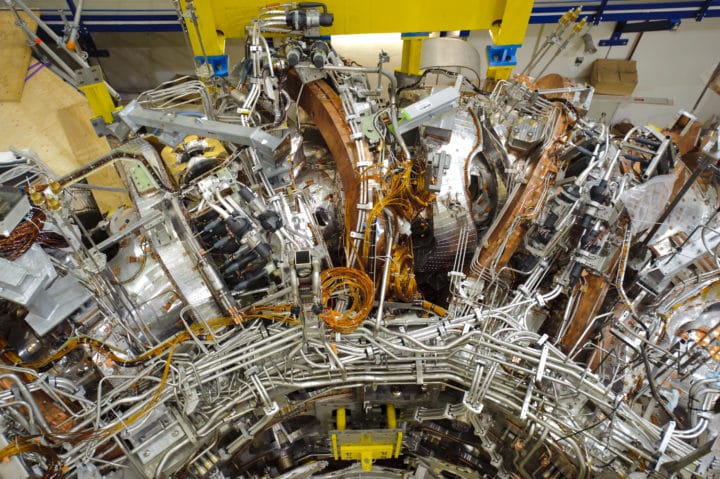

Max-Planck-Gesellschaft, Institute for Plasma Physics

The development of the fusion facility Wendelstein 7X would be impossible without reliable and precise temperature recording. Our modules are also used in this project, as there are no comparable alternatives on the market.

The following are the most important characteristics of the module A105, which is available as Q.bloxx for top hat rail mounting, as a mobile system Q.brixx or in a 19″ version:

- 4 galvanically separated input channels for Pt100, Pt1000 and for resistance measurement

- Measurement precision

0.05 °C - Temperature stability

0.02 °C per 10 °K change

in ambient temperature - Analog/digital conversion

24 bit - Filter, linearization, min/max and alarm independently configurable for each channel

- Versions can be provided for special sensors, for example cryosensors (TVO, Cernox)

More articles

Wendelstein 7-X Stellarator

After 9 years in construction, the stellarator (nuclear-fusion machine) of the Max Planck Institute in Greifswald generated plasma for the first time on December 10, 2015. The reactor had been gradually ramped up over the past 12 months. The event was given extensive coverage in the media. Gantner Instruments specially developed sensors for temperature and strain measurement for the project, which are otherwise unavailable on the market.

Read more...Webinar – Crate.io + Gantner Instruments: Real-time energy grid control based on big data

With the increase in renewable energy sources, the challenge for electric grid operators to keep grid frequencies stable has become even more significant. Constant data collection is essential for modern control technology and makes it possible to execute controls more quickly, whereby the use of smart grids can be further optimized.

Read more...Q.series X A107 SV: Universal Measurement Module with Sensor Supply

Gantner Instruments' Q.series X A107 4 x Lemo 2B SV module is an adaptable and precise universal measurement module designed for engineers who need accurate data acquisition in distributed installations. This module, which is part of the modular and scalable Q.series X product family, now includes programmable sensor supply voltage and current limit capabilities per channel.

Read more...Monitoring Solutions for Asset Management

Gantner Instruments provides monitoring solutions for both static and dynamic equipment in terms of vibration monitoring of piping, vessels, heat exchanger, large machines (static) and pumps, fans, and turbines (dynamic). Based on the robust and flexible Q.series modules with its decentralized signal conditioning and data acquisition modules, a very reliable and cost effective trend and condition monitoring solution is available and working also under harsh environmental conditions. With the monitoring solution of Gantner Instruments the asset becomes smart and delivers detailed status information.

Read more...