Q.station X

Q.station X: Your Next-Gen Solution

The Q.station X is an intelligent controller that can be combined with Q.series XL modules to form custom DAQ systems. The Q.station X Controller and Q.series XL measurement modules are designed for industrial and experimental testing. Q.series XL products are exceptionally well suited for performing highly synchronized, multi-channel measurements of electrical, mechanical, and thermal signals on engine and component test benches and long-term process monitoring applications.

Exploring the Capabilities of Q.station X

The Q.station X connects up to 64 I/O modules for reliable 24/7 operation. Create up to 20 independent, PC-less multifrequency data loggers up to 100 kS/s while measuring up to 100 kHz per channel and utilizing powerful arithmetic functions. Fieldbus interfaces for CAN, Modbus TCP/IP, Modbus RTU, PROFIBUS, PROFINET, and support for publish/subscribe and messaging protocols, e.g., OPC UA, DDS, and MQTT and custom controller plugins for customer-specific communication protocols.

Features

- For computer-independent data logging

- Up to 64 I/O modules connectable

- Distribute and Daisy Chain I/O modules or connect directly

- Multiple sampling rates

- RT Linux operating system for reliable 24/7 operation

- CAN bus port

- ModbusTCP, Modbus RTU with external adapter, e.g., RS485 to USB

- 2 USB ports for, e.g., GPS mouse

- Time synchronization with NTP, PTP, IRIG

- test.con available (XT-version)

- Multiple interface options, e.g., OPC UA, DDS, and MQTT

Data buffers, stream processors, Time synchronization, arithmetic engine, User-defined code (Plugins).

Mixed-Signal, Multi-Frequency Data Buffering

Efficient Data Stream Processing

- Software application for real-time data stream processing

- Collect, process, and safely log data to different destinations

- Concept is based on shared memory with multiple access points and avoiding redundant data transfer to optimize performance

- Process data streams with joins, aggregations, filters, arithmetic calculations, etc.

- API to interface with third-party data streams from external measurement & control devices

Q.station X Key Features

| Interfaces | Q.station X |

| Ethernet TCP / IP | yes |

| EtherCAT | yes |

| ProfiNet | yes |

| Connectivity | Q.station X |

| Configuration (local or remote) via GI.bench | yes |

| Modem | (Optional external device) |

| GI.cloud connection | yes |

| Data Logging / Control | Q.station X |

| Sampling rate | Up to 100 kHz / 4 MHz with Q.boost A101 |

| Continuous Logging | yes |

| Event-based Logging | yes |

| Triggered Logging | yes |

| # of data loggers with arithmetics / filters | 20 |

| Data Storage | Q.station X |

| RAM [MB] / Flash [MB] | 500 / 4000 |

| SD card | yes |

| USB Expandable | 2 slots |

| DAQ Modules | Q.station X |

| Number of DAQ modules | Connect up to 64 Q.series X modules |

| Digital inputs and outputs | 6 inputs / 4 outputs |

| Analog input | - |

| Programming | Q.station X |

| Programmable edge computing (Real-time) | yes |

| Programmable edge computing (Non Real-time) | yes |

| Can install apps (external) | yes |

| Display with touch (optional) | yes |

| Typical power consumption [W] | < 12 |

Specialized Q.station X Variants

The Q.station X SSD is an intelligent controller with an extension slot with a built-in 1 TB Solid State Drive (SSD) for internal measurement data storage.

The Q.station X ETH is an intelligent controller that includes an extension slot for an additional 1 GBit RJ-45 Ethernet interface for operation in two independent networks.

Need help deciding which Q.station X is best for you?

Are you interested in the Q.station X controller but don’t know which variant is best for you? Our engineers can quickly help you personalize a DAQ system around your needs.

Advantages of Test.con (XT-version) for Q.station X

If you require the use of test.con, then you would need to use a Q.station XT controller. If you do NOT require test.con, then you would use the Q.station XB controller.

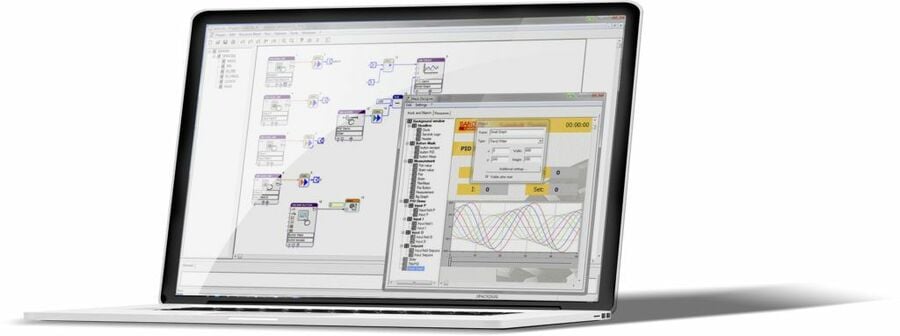

test.con is used to graphically program application-specific math functions, logic, and embedded HMI screens via a PC and then compiles and runs them on the Q.station XT controller. Programming in test.con is simple: drag the desired functions from an extensive library onto the worksheet and ‘wire’ the functions in the correct sequence – no code is required. You can also create macros consisting of multiple functions to improve clarity and simplify more complex routines.

Designing HMI pages

The integrated Mask Designer in test.con allows you to create a touch-screen HMI for an external display (connected to a Q.station XT) or a network-connected PC. By mapping the display and control functions for the attached controller’s variables, one can create a very powerful data logging, automation, and HMI display system that runs completely on the connected controller — without the need for a tethered PC or any additional external software packages.

test.con Studio is a free programming system that you can install on any number of computers. Licensing of software is not required. test.con Studio runs on all designated controllers, such as the Q.station XT.

Find more information

- Installation and initial steps

- Documentation

- Forum Community

Application Examples

AE

Measuring temperature in components of Hybrid Electric Drives

Click here to request

access to every

GI Application Example

Applications

The versatility of Gantner DAQ products makes them ideal for:

GI Productfinder

Find the right products for your application in a matter of seconds.

FAQ

These are frequently asked questions regarding our Q.station X:

The exact procedure will depend on the manufacturer and model of the controller, so always consult the device’s manual. Generally:

Power cycle / Soft Reset: The simplest reset is often just power cycling the device (turning it off and on). Some controllers have a dedicated reset pin or button that triggers a reboot without removing power. This type of reset re-initializes the controller but does not erase the configuration. For example, many PLCs have a small recessed reset button you can press to restart the CPU. This helps recover from a freeze or to get the controller to re-run its startup routine.

Factory Reset (Restore defaults): To fully reset all settings to factory defaults, controllers often require a specific button sequence or jumper setting. For instance, a device might require holding down a reset button for more than 5 seconds, or pressing a tiny “INIT” switch while powering on, etc. As an example, one Gantner Instruments controller requires tapping the reset button, then holding it for 5 seconds, then releasing and tapping again, to clear all settings. This kind of reset wipes user configurations and returns the device to default IP addresses, cleared memory, default passwords, and so on. Always follow the exact instructions – the timing and sequence can be important.

Reset via Software: Some controllers can be reset remotely through software commands or their web interface. For example, issuing a “factory reset” command over a console or using the vendor’s configuration software to send a reset instruction. Ensure that you have saved any needed configurations, as factory resets cannot be undone.

After Reset: Once a controller is reset, you may need to reconnect and reconfigure it. If it’s a networked device, it might revert to a default IP or hostname. If it’s a PLC, it might clear the program from memory (unless it’s stored in non-volatile memory separately). Consult the manual to understand what is cleared by a factory reset (e.g., user program, communication settings, I/O calibration, etc.).

In summary, resetting a controller typically involves either pressing a hardware reset button or performing a specific power-on sequence. For a simple reboot, a quick press or power cycle suffices; for a deep reset to defaults, a longer press or special procedure is used. Always ensure you have backed up configurations and understand the reset procedure from the manufacturer’s documentation to avoid unintended data loss.