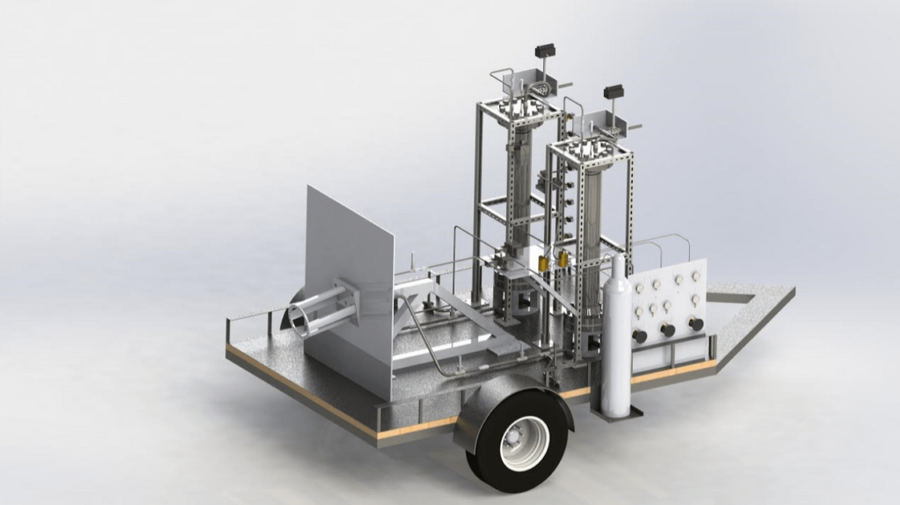

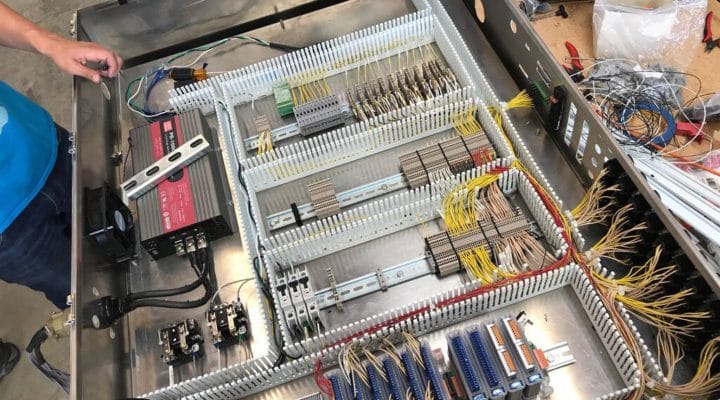

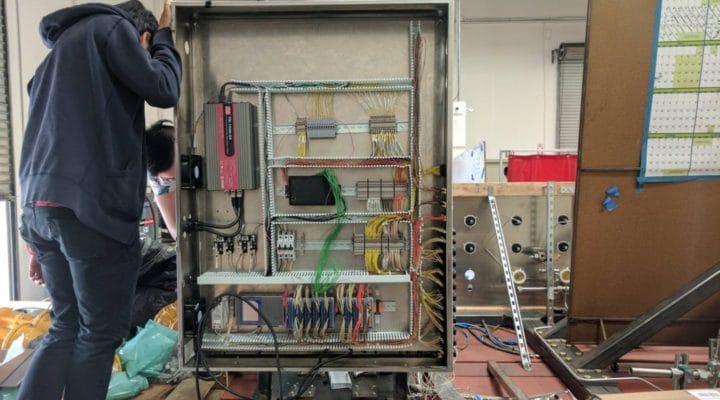

The Gantner Instruments DAQ system is designed to receive signals from the test stand’s sensors and send reports back to the operator for monitoring and control. The Q.station controller is being programmed to automatically respond to errors and actuate fire safety valves to prevent System failures.

Construction recently began on the test stand by the SEDS software and electronics team. Gantner Instruments Technical Support team provided training on the use of the hardware and software and help with the initial configuration of the test stand DAQ system.

We will post more updates as construction continues on the Colossus project!

More information about the project can be found here:

More articles

Transform data into insights

A monumental challenge for engineers is not just how to acquire data in testing, but how to store and preserve such large volumes of it

Read more...Standalone E-drive testing in 3 simple steps

Automobiles have a variety of electrically operated drives. Be it the sunroof, the window lifter, the seat adjustment or the trunk lid, everywhere you look, you’ll find electric motors that provide us comfort in our cars.

Read more...Apprenticeship at Gantner Instruments

We open our doors to exclusive insights into our company by talking to our apprentice, Philip, about his experiences with his apprenticeship at Gantner Instruments. In this interview, Philip tells us his story, from his search for an apprenticeship to his everyday life with us, and provides a deeper insight into a corporate culture that is much more than just a workplace.

Read more...Airbus has selected the Q.raxx EC with EtherCAT interface as the integrated control and measurement solution for their component structural testing lab

Airbus Helicopters is a world-leading designer and manufacturer of helicopters. The company’s product line offers the full spectrum of rotary-wing aircraft solutions for civil, government, military, law enforcement and parapublic uses. With the growth in business and innovation of their product offering, Airbus Helicopters decided to modernize their structural test facility at their main facility in Donauwörth, Germany.

Read more...