High Voltage Measurement

Accurate and safe high-voltage (HV) measurements are crucial in the development and validation of electric vehicles (EVs), battery systems, fuel cells, electrolyzers, and power electronic components. These applications demand precise measurement of voltage, current, temperature, strain, and acceleration at potentials reaching up to 1500 VDC. Reliable HV data ensures system performance and safety compliance, while also accelerating innovation.

Understanding High-Voltage Measurement

High-voltage measurement involves the precise acquisition of electrical parameters—voltage, current, and temperature—in systems operating at elevated potentials (up to 1500 VDC). HV measurements differ significantly from low-voltage counterparts, requiring specialized instrumentation, robust isolation methods, and stringent safety protocols (typically CAT III/CAT IV compliance).

Measurement Techniques in High-Voltage Environments

The techniques used for high-voltage measurement are designed to address the unique challenges posed by the high electric potential.

Proper selection of equipment and adherence to safety standards are mandatory when working in HV conditions to prevent hazards and ensure accurate data.

- Voltage Measurement (AC & DC): Measuring the overall voltage of a battery pack, fuel cell, or energy storage system up to 1500 VDC (approximately 1060 VAC on a 50/60 Hz pure sine wave grid) requires precise instrumentation.

- Lower Voltage Signals on High Potential: Measuring the 3.6 or 4.2 V of battery cells within an 800 VDC or higher-rated battery pack requires high permanent isolation of the measurement channels from each other, their power supply, and communication interface, as well as a high-accuracy low-voltage measurement range of ±5 V or ±10 V.

- Current Measurement: Utilizing current transducers (CT) or shunts to accurately measure current within high-voltage environments.

- Temperature Measurement on High Voltage Potential: Accurately measuring the tiny µV signals from thermocouples or resistance from RTDs (Pt100/Pt1000) on up to 1500 VDC potential.

- Strain Measurement on High Voltage: Monitoring mechanical strain in components subjected to high voltage.

- Acceleration Measurement on High Voltage: Measuring acceleration within systems operating at high voltage levels.

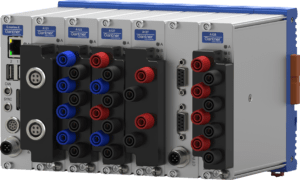

Gantner High-Voltage DAQ Solutions

Gantner Instruments’ high-voltage DAQ modules deliver reliable and accurate measurements essential for applications such as EV battery testing, power electronics evaluation, and renewable energy systems. These modules provide permanent galvanic isolation, including channel-to-channel, power supply, and interface isolation, to ensure safe and precise data acquisition.

Q.series X A121 High Isolation Multi-Purpose Module

Universal module measuring voltages (±100 mV to ±10 V), currents (±25 mA), thermocouples, RTDs, strain gauges, and IEPE sensors. Offers permanent 1200 VDC isolation suitable for diverse measurements in EV testing and power grid monitoring.

Q.series X A123 High Isolation Module for Voltages

Specialized for detailed voltage measurement on battery cells and stacks, providing robust 1200 VDC isolation, ensuring precise voltage analysis of fuel cells and energy storage systems.

Q.series X A124 Plus High Isolation Module for Thermocouples

Dedicated to precise thermocouple measurements with full isolation (1500 VDC), ideal for thermal management monitoring in HV battery packs and power electronics.

Q.series X A127 and A127 2CV/4CV for Electrical Power Measurement

Designed for comprehensive power analysis with high-voltage and current inputs, essential for detailed efficiency and power-quality evaluation of inverters and electric drives.

Q.series X A128 and A128 Plus for Dynamic High Voltage

Optimized for dynamic voltage measurements at potentials up to 1500 VDC, ideal for transient analysis and rapid voltage fluctuations in advanced powertrain testing.

Q.series X A138 for Battery Cell Voltage Measurements

The A138 excels in precise battery cell voltage measurement, providing highly accurate monitoring essential for battery testing and evaluation, particularly in large-scale automotive battery systems.

Unique Features

Gantner modules feature permanent galvanic isolation up to 1500 VDC, robust signal conditioning, and high-accuracy analog-to-digital converters, delivering reliable measurement data under the most challenging conditions.

Integration and System Compatibility

Our modules integrate seamlessly via standard industrial interfaces (EtherCAT, CAN, Ethernet), enhancing system flexibility. Combined with GI.bench software, Gantner solutions enable efficient setup, configuration, and data analysis tailored specifically for HV measurement applications.

Specialized HV Testing Solutions by Gantner Instruments

Stack Monitoring Unit (SMU)

High-isolation, high-channel-density modules for cost-effective cell voltage and thermocouple measurements in high-voltage battery packs, fuel cells, and electrolyzers.

Power Analysis with the GPA Series

Precise, real-time measurement of voltage, current, power quality, harmonics, and power factor for renewable energy systems, grid quality studies, and EV drivetrains.

Electrochemical Impedance Spectroscopy (EIS)

In-depth analysis for battery and fuel cell characterization, aiding in performance optimization, state-of-health (SoH) assessments, and production quality control.

Where is high-voltage test and measurement used?

Gantner Instruments provides High-Voltage Testing solutions for all battery development and qualification steps, including:

This testing determines a battery’s lifecycle by evaluating its performance through repeated charging and discharging cycles. It helps to ascertain how many times a battery can be used before it deteriorates, which is vital for ensuring the longevity and reliability of energy storage systems in electric vehicles and renewable energy installations.

Safety testing simulates a wide range of environmental conditions and potential failure scenarios to determine the thresholds at which batteries fail. This includes tests for thermal runaway, mechanical shock, and electrical abuse, ensuring that batteries can withstand extreme conditions without posing safety risks.

Performance testing evaluates a battery’s efficiency under different climatic conditions. This testing can be customized to meet specific requirements, ensuring that batteries perform optimally in diverse environments, which is crucial for applications ranging from portable electronics to electric vehicles.

These tests demonstrate the quality and reliability of batteries under various environmental stressors. They include vibration, shock, electromagnetic compatibility (EMC), thermal cycling, corrosion, dust, salt, and humidity tests. Such comprehensive testing ensures that batteries can operate reliably in harsh and fluctuating environmental conditions.

Transport testing ensures that batteries can be safely transported by adhering to international standards, such as the United Nations requirements (UN 38.3). This includes tests for altitude simulation, thermal cycling, vibration, shock, and short-circuit conditions, ensuring safe and compliant transportation of batteries, modules, and cells.

Impedance spectroscopy analyzes the electrochemical properties of batteries, providing insights into their capacity, cycling lifetime, shelf life, current-carrying capacity, and low-temperature performance. This method is crucial for both research and development, as well as production quality control, as it helps refine battery design and ensure consistent performance and safety.

Charge/discharge cycle testing

This testing determines a battery’s lifecycle by evaluating its performance through repeated charging and discharging cycles. It helps to ascertain how many times a battery can be used before it deteriorates, which is vital for ensuring the longevity and reliability of energy storage systems in electric vehicles and renewable energy installations.

Safety (abuse) testing

Safety testing simulates a wide range of environmental conditions and potential failure scenarios to determine the thresholds at which batteries fail. This includes tests for thermal runaway, mechanical shock, and electrical abuse, ensuring that batteries can withstand extreme conditions without posing safety risks.

Performance testing

Performance testing evaluates a battery’s efficiency under different climatic conditions. This testing can be customized to meet specific requirements, ensuring that batteries perform optimally in diverse environments, which is crucial for applications ranging from portable electronics to electric vehicles.

Environmental and thermal testing

These tests demonstrate the quality and reliability of batteries under various environmental stressors. They include vibration, shock, electromagnetic compatibility (EMC), thermal cycling, corrosion, dust, salt, and humidity tests. Such comprehensive testing ensures that batteries can operate reliably in harsh and fluctuating environmental conditions.

Transport testing

Transport testing ensures that batteries can be safely transported by adhering to international standards, such as the United Nations requirements (UN 38.3). This includes tests for altitude simulation, thermal cycling, vibration, shock, and short-circuit conditions, ensuring safe and compliant transportation of batteries, modules, and cells.

Challenges Faced in High-Voltage Measurement

Safety Concerns

Ensuring the safety of technicians and engineers who work with high-voltage systems is of paramount importance. High-voltage environments pose inherent risks, including severe electrical shocks or arcs that can result in injuries or fatalities.

Signal Integrity

High-voltage environments are often characterized by electromagnetic disturbances that can significantly corrupt measurement data.

Accuracy and Precision at High Potentials

Due to their critical roles in infrastructure, high-voltage systems operating at high potentials demand exceptionally accurate measurements. Even minor discrepancies can lead to significant problems, such as equipment malfunctions or system failures.

High Power Handling

Devices like electric vehicle chargers or inverters for solar panels combine high voltages with substantial currents, requiring durable measurement tools that can withstand these conditions without degrading.

Long-term Stability and Reliability

Durability is crucial in high-voltage measurement instruments, as they must perform consistently over time under potentially harsh environmental conditions.

Adaptability for Rising Voltages

As technology advances, measurement solutions must accommodate progressively higher voltages without compromising on accuracy or reliabi

External Interference

Operating high-voltage measurement equipment near other electronic devices can introduce additional noise and errors.

Technology Integration

Integrating conventional high-voltage measurement techniques with advanced digital technologies is challenging yet necessary to enable features such as real-time data analytics and smart grid functionalities.

Gantner Instruments delivers unmatched precision and safety in high-voltage measurement, empowering your innovations with robust, reliable data acquisition solutions.

Why Gantner for High-Voltage Measurement?

Superior Permanent Isolation

Permanent 1500 VDC isolation between channels, channel-to-power supply, and channel-to-interface ensures accurate and reliable measurements critical for battery packs, modules, and cells.

Precision Tailored for EV Battery Testing

Gantner Instruments’ high-voltage DAQ systems precisely evaluate EV batteries, providing up to 1500 VDC permanent isolation for safe, accurate measurements. Customizable connectors, modular design, and synchronized video integration offer scalable solutions tailored for battery testing, safety validation, and advanced development scenarios.

Proven Expertise and Innovation

With decades of experience, Gantner Instruments consistently develops advanced measurement solutions to meet the complex demands of various industries, delivering exceptional accuracy, stability, and reliability.

Comprehensive Product Lineup

Gantner Instruments offers specialized high-voltage measurement solutions for voltage, current, and temperature, designed to excel in demanding applications such as battery testing, power analysis, and high-voltage monitoring.

Comprehensive Support and Training

Gantner Instruments offers expert structured training through GI.academy, and our technical support team provides expert guidance and solutions, assisting with setup and ongoing maintenance to ensure customers maximize the value of their high-voltage measurement systems.

Customized connectors and form factors

Our modular systems support customized connector types and synchronized video integration, enabling scalable, flexible setups optimized for battery testing, safety validation, and advanced research scenarios.

Superior Electrical Isolation and Safety

Gantner Instruments prioritizes user safety and data integrity with robust electrical isolation, safeguarding personnel and equipment in high-voltage environments to ensure consistent performance.

Advanced Signal Processing and Accuracy

Our modules feature sophisticated signal processing, including anti-aliasing filters, digital filtering, linearization, and RMS calculations, paired with high-resolution A/D conversion, delivering precise data that meets stringent industry standards.

Seamless Integration and Flexibility

Compatible with standard interfaces such as EtherCAT, CAN, and Ethernet, our solutions easily integrate into diverse measurement setups. GI.bench software streamlines configuration, visualization, and analysis.

Industry-Proven Reliability

Leading organizations across energy, automotive, aerospace, and industrial sectors trust Gantner Instruments’ proven track record of delivering high-quality, dependable measurement solutions.

Application Examples

Gantner’s cutting-edge DAQ technology is trusted globally for applications in the mobility, aerospace, civil engineering, and energy sectors. Choose from the following industry examples to discover the most versatile DAQ on the market.

AE

Measuring temperature in components of Hybrid Electric Drives

Click here to request

access to every

GI Application Example

Who trusts Gantner for High-Voltage Test & Measurement?

Leading manufacturers and testing laboratories, such as Bosch Battery Systems, GM, and TÜV SÜD, use solutions based on the Q.series X.