NOV (National Oilwell Vacro) is a global company in the fields of drilling and conveying technology. NOV supports the world’s most advanced drilling solutions in the oil and gas industry.

Here almost 150 measuring channels are used in a test system:

- 10 x IEPE with 5 x Q.bloxx A101

- 24 x current with 3 x Q.bloxx A108

- 12 x Pt100 with 3 x Q.bloxx A107

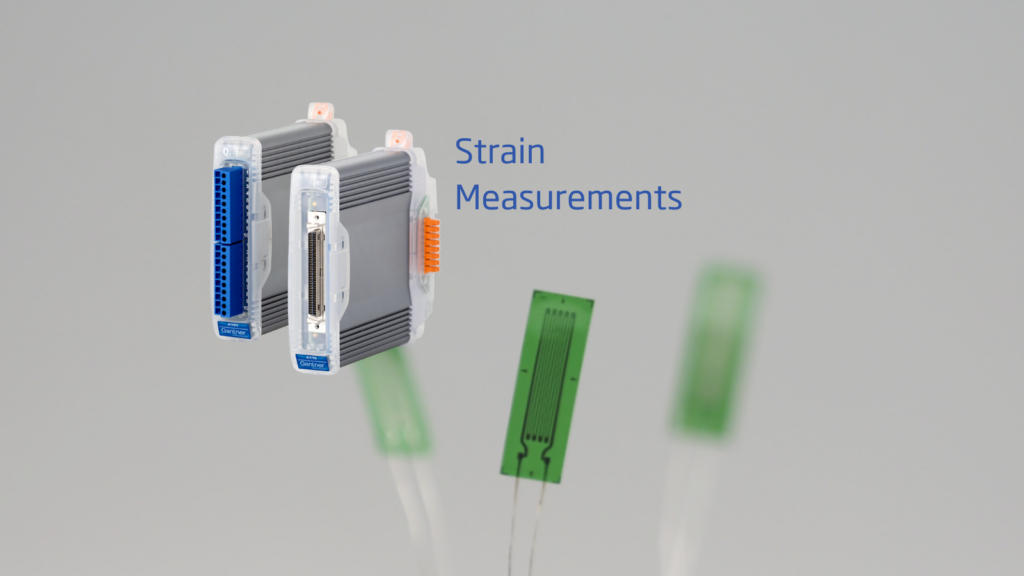

- 96 x SG with 12 x Q.bloxx A116

- Multiple digital I/Os

The measured data is recorded at a sample rate of 10 kHz. A data logger was configured in the Q.station test controller that records the conditioned and raw data. The recorded data is transferred to a SQL database using the test.node server software.

At present, four test systems are being built; with additional systems being planned. Testing is performed in cooperation with our Danish partner IPC Teknik ApS.

More articles

Boeing 777X folding wingtip

Boeing is looking to debut a new and ambitious aircraft in 2020: the 777X, a dual-aisle, twin-engine aircraft that is built around fuel efficiency. The aircraft is designed to use 12% less fuel than any competing aircraft and 20% less fuel than today’s 777.

Read more...Airbus has selected the Q.raxx EC with EtherCAT interface as the integrated control and measurement solution for their component structural testing lab

Airbus Helicopters is a world-leading designer and manufacturer of helicopters. The company’s product line offers the full spectrum of rotary-wing aircraft solutions for civil, government, military, law enforcement and parapublic uses. With the growth in business and innovation of their product offering, Airbus Helicopters decided to modernize their structural test facility at their main facility in Donauwörth, Germany.

Read more...Q.series X D107 SV: Digital Measurement Module with Sensor Supply

The Q.series X D107 2 x Lemo 2B SV module from Gantner Instruments provides a comprehensive solution for digital signal acquisition and sensor supply needs. Designed for distributed installations requiring precise digital measurements, this module enhances the Q.series product family's robust offering.

Read more...6 Tips for Stress-free Strain Measurement during Fatigue Testing of Aircraft Structures

Strain is the single most important measurement during aircraft fatigue testing. The accuracy and precision of strain gauge measurements is of the greatest importance to exactly determine the durability and damage tolerance of a structure. The higher a structure is in the ‘pyramid of test’, the higher the test complexity, number of measurement channels, and data produced. On top of that the risk in terms of time delay and cost associated to a test program increases more than proportional with the increase in test complexity. Here are six tips to help you choose the right data acquisition system for your fatigue test:

Read more...