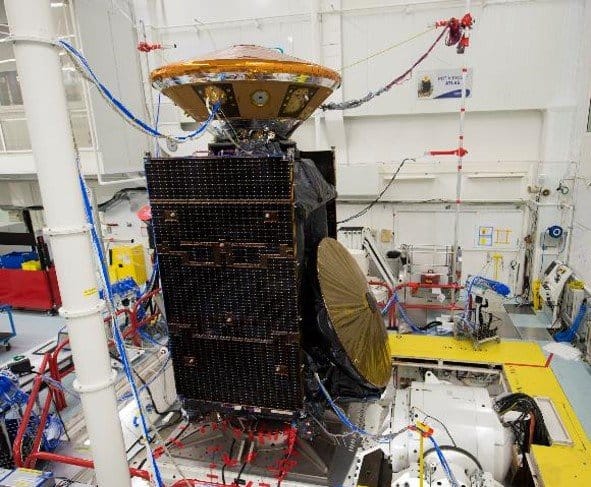

Space is an exceptionally challenging industry for new product development and quality control. Equipment often has to be lightweight, robust and durable because it is subject to extreme environments, including exposure to extreme heat and cold cycling, ultra-vacuum, high energy radiation, and shock and vibration of launch. Extensive testing ensures that the final product will achieve its intended purpose while in Earth’s orbit.

To learn more about Gantner Instruments’ latest innovations in data acquisition hardware and software we cordially invite you to send a request for a meeting with Stephan Ploegman.

Gantner Instruments offers data acquisition solutions for space testing that border on the limits of the possibility, such as temperature measurement using a Pt100 sensor with a stability of 0.02° C/K. We select superior stability components for our strain gage measurement, which guarantee optimal results due to their ingenious circuitry. We can accurately measure frequencies from less than 1 Hz to 1 MHz. And we measure strain, pressure, acceleration, and temperature in an environmental test chamber under cryogenic and ultra-vacuum conditions using our fiber optic measurement technology.

ROCKET ENGINE TESTING

Thrust, pressure, temperature, fuel flow and vibration characterization.

SPACE SIMULATION TESTING

Environmental testing including solar simulation, thermal vacuum, and thermo-elastic deformation testing.

STATIC STRUCTURAL TESTING

Verification of static strength and determination of the load distribution across the rocket structure.

VIBRATION TESTING

Simulate the load conditions that a payload must survive during the rocket launch.

Contact for Appointments

Stephan Ploegman

S.Ploegman@gantner-instruments.com

Stephan will be happy to answer all your questions and meeting you at the Space Tech Expo.

Event

Space Tech Expo Europe

Messe Bremen

Bremen

Nov 19 ‑ 21, 2019

Booth B50

More articles

Space Tech Expo Europe 2019

Gantner Instruments will participate in the B2B matchmaking event as part of the Space Tech Expo & Conference Europe. The Space Tech Expo & Conference Europe (19 – 21 November, 2019) is the largest dedicated space technology trade fair in Europe. The three-day event will give the European space industry a focused marketplace for the design, manufacturing and testing of spacecraft, satellite, launch vehicle and space-related technologies. The Space Tech Expo B2B Matchmaking will take place in the exhibition hall at the Bremen booth B50.

Read more...Measure the evolution of battery technology

New ground-breaking products and powerful solutions for fast and accurate Cell, Module and Pack testing

Read more...E-TECH EUROPE 2024

Gantner Instruments is participating in E-TECH EUROPE 2024, the international trade show for advanced batteries and innovative technologies essential for automotive and electric vehicle production.

Read more...FHV Jobmesse 2024

Gantner Instruments will be part of the largest job fair in the region on March 15, 2024.

Read more...