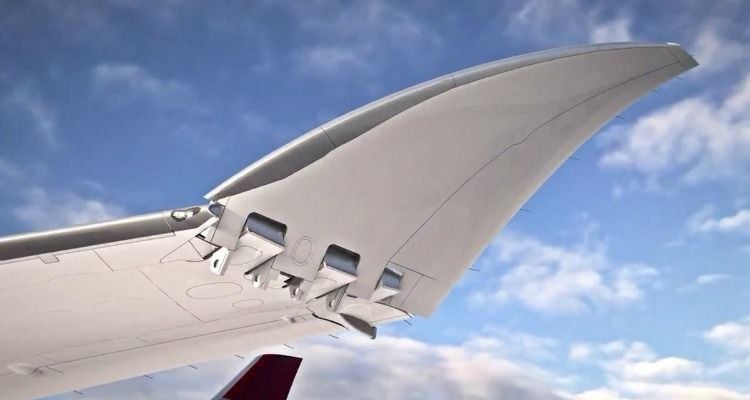

Boeing credits much of the 777X’s improved fuel efficiency to the aircraft’s composite wings, which stretch 71.8m (236ft) from wingtip to wingtip. To make sure that the 777X will fit in existing airport gates, the wingtips will be able to fold upward by 3.5m on each side.

Liebherr-Aerospace has been selected to design, develop, and manufacture the folding wing tip system. With its motor and rotating actuator, this system will fold the wing tip after landing, thus reducing the wingspan of the new wide-body aircraft by 7 meters. The folding wingtip system is the first of its kind in commercial aviation, so extensive testing is required. Not only to ensure passenger convenience (passengers should actually not hear loud noises or significantly feel the action of the mechanics), but also from a safety perspective. Failures or external threats must not compromise both primary and backup systems simultaneously. A wingtip failure will ground the aircraft!

For this critical test program Liebherr-Aerospace uses a Gantner Instruments Q.series system to perform the primary data acquisition tasks. The flexibility of the Q.series system, in combination with a wide variety of commercial off-the-shelf I/O modules, allows Liebherr-Aerospace to maximize test equipment utilization, test bench availability and overall test lab performance. On top of that, the Q.series measurement system features a set of specific features that are crucial for successful aircraft component testing. So does the Q.series system come with precise nanosecond time synchronization between all modules and to external time references, eliminating the uncertainty of data skew during critical test conditions.

The build-in test automation functionality enables quick and efficient monitoring and processing of measurement data, minimizing manual system handling and shortening overall test duration time. And last but not least, the Q.series system has 3 levels of redundancy for assured data availability. Measurement data can be transferred to 2 data storage locations simultaneously and 1 data location for backup.

More Information

Click here to receive a personalized Application Example Pack containing the real-world application example “Boeing 777X Folding Wingtip System Test” and a few bonus application examples within the Aerospace industry!

More articles

Automotive Testing Expo India 2023

The path to reduced product development cycles, more efficiency, and better durability starts with Gantner Instruments at Automotive Testing Expo India 2023.

Read more...Aerospace Testing Symposium 2022

Gantner Instruments will be sponsoring the Aerospace Testing Symposium, which takes place from September 27-28 at London Farnborough Airport, UK. Discover and demo our latest products, technology and solutions at Booth 7!

Read more...How to enhance your EtherCAT master with best real-time DAQ

Connectivity and flexible integration of our high-accuracy and high-speed I/O modules into any automation system is in our DNA. Therefore you are now able to integrate our high-performance Q.series X I/O modules into all industry standard EtherCAT masters like TwinCat, Koenig KPA, NI VeriStand, and Acontis.

Read more...EtherCAT performance combined with industry leading DAQ: 5 benefits you’re missing out on

We have compiled a list of the 5 most significant benefits of using an EtherCAT-based data acquisition system. If you’re not already familiar with EtherCAT, prepare to be enlightened. If you’re among the many engineers that use EtherCAT in your testing lab then you can consider this a confirmation of why you do what you do – and an excellent place to direct those who still think Industrial Ethernet is not suitable for high-performance testing applications.

Read more...