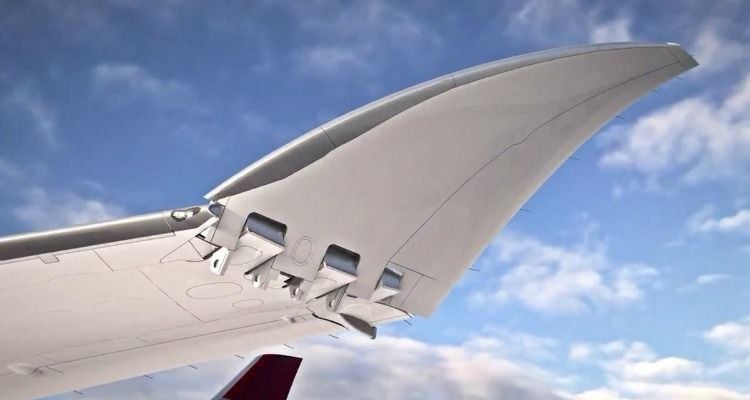

Boeing credits much of the 777X’s improved fuel efficiency to the aircraft’s composite wings, which stretch 71.8m (236ft) from wingtip to wingtip. To make sure that the 777X will fit in existing airport gates, the wingtips will be able to fold upward by 3.5m on each side.

Liebherr-Aerospace has been selected to design, develop, and manufacture the folding wing tip system. With its motor and rotating actuator, this system will fold the wing tip after landing, thus reducing the wingspan of the new wide-body aircraft by 7 meters. The folding wingtip system is the first of its kind in commercial aviation, so extensive testing is required. Not only to ensure passenger convenience (passengers should actually not hear loud noises or significantly feel the action of the mechanics), but also from a safety perspective. Failures or external threats must not compromise both primary and backup systems simultaneously. A wingtip failure will ground the aircraft!

For this critical test program Liebherr-Aerospace uses a Gantner Instruments Q.series system to perform the primary data acquisition tasks. The flexibility of the Q.series system, in combination with a wide variety of commercial off-the-shelf I/O modules, allows Liebherr-Aerospace to maximize test equipment utilization, test bench availability and overall test lab performance. On top of that, the Q.series measurement system features a set of specific features that are crucial for successful aircraft component testing. So does the Q.series system come with precise nanosecond time synchronization between all modules and to external time references, eliminating the uncertainty of data skew during critical test conditions.

The build-in test automation functionality enables quick and efficient monitoring and processing of measurement data, minimizing manual system handling and shortening overall test duration time. And last but not least, the Q.series system has 3 levels of redundancy for assured data availability. Measurement data can be transferred to 2 data storage locations simultaneously and 1 data location for backup.

More Information

Click here to receive a personalized Application Example Pack containing the real-world application example “Boeing 777X Folding Wingtip System Test” and a few bonus application examples within the Aerospace industry!

More articles

Airbus Helicopters Chooses Gantner to Upgrade their Fatigue Test Cells

Airbus Helicopters (formerly Eurocopter Group) is a global helicopter manufacturing and support company. It is the largest in the industry in terms of revenues and turbine helicopter deliveries. With the growth and advancement of their product offer, Airbus Helicopters identified a need to upgrade their component test benches at their newly enhanced manufacturing location in Donauwörth, Germany.

Read more...Voltage IEPE Sensor Measurement Data Acquisition (DAQ) with Q.bloxx A111

Q.bloxx is the ideal DAQ solution for widely distributed installations, electrical panels, and environmental enclosures. Q.bloxx measurement modules provide integrated signal conditioning and arithmetic functions, packaged in modular, DIN Rail mountable enclosures that easily snap together for quick system expansion.

Read more...New Monitoring Solution – Q.series Portable

For short-term or rout-based condition monitoring of various assets we now provide a portable system solution. Our new Q.series Portable based on Q.station 101 and OEM-boards for analog and digital inputs contained in a robust transport case is fully engineered and ready to use ‘out of the box’. The electronic boards and the power supply system are mounted on shock absorbers to withstand heavy-duty work under harsh environments in the field.

Read more...The IET Nuclear Engineering for Safety, Control and Engineering 2022

Fully supported by the United Kingdom Office for Nuclear Regulation (ONR), Nuclear Engineering for safety, control and security addresses the challenges faced by those working in the sector. As usual there will be a mix of practical guidance for today’s issues as well as exploring new technology and innovation for future application.

Read more...